Pre-plate Vibratory Finishing is unmatched for its low production cost per piece. With the proper application of media and compounds, finishes in the 10 to 4 microinch range are possible. Die-cast parts and products can be optimally processed and prepared for plating. Vibratory finishing can remove flash and burrs and also refine surfaces. The process can also serve as a super active degreaser and chip remover or roughen plastics and metals for good coating adhesion.

Vibratory deburring works by causing the media and parts to rub together from the vibration of the tub or bowl in a circular motion. While the load is scrubbing, the vibratory action also causes the load to circulate at a slow rate. This circulation keeps the pieces separated to avoid impinging on each other. The frictional forces work both on the outer surface of the piece, and also on the inside to work recesses, cavities, or blind holes. Cleaners or compounds are added for cleaning and burnishing. Vibratory finishing affects a rapid action due to the high G-force and the fact that the entire load is being cut at the same time.

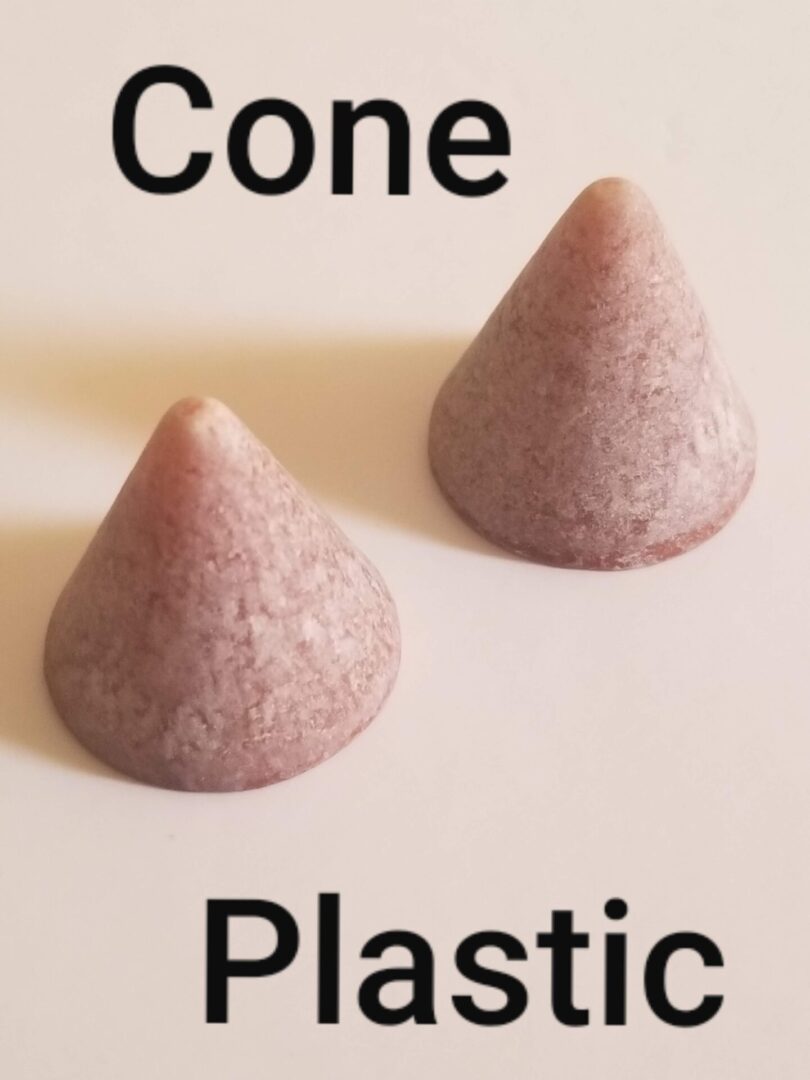

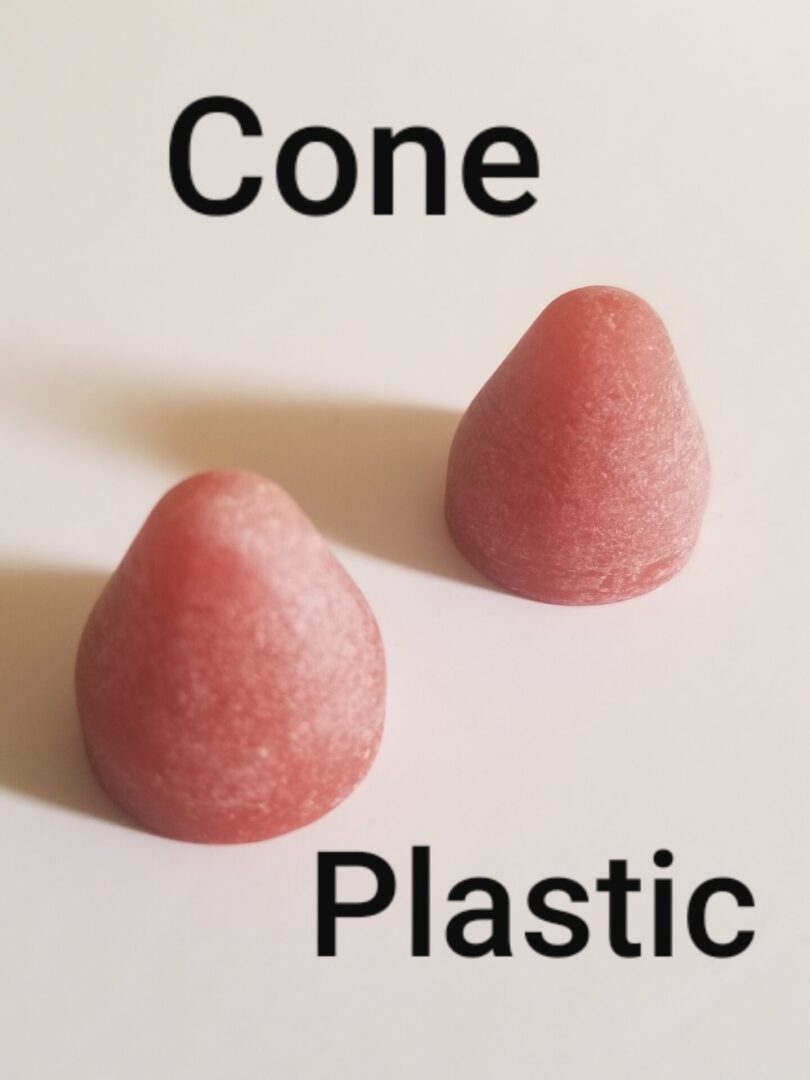

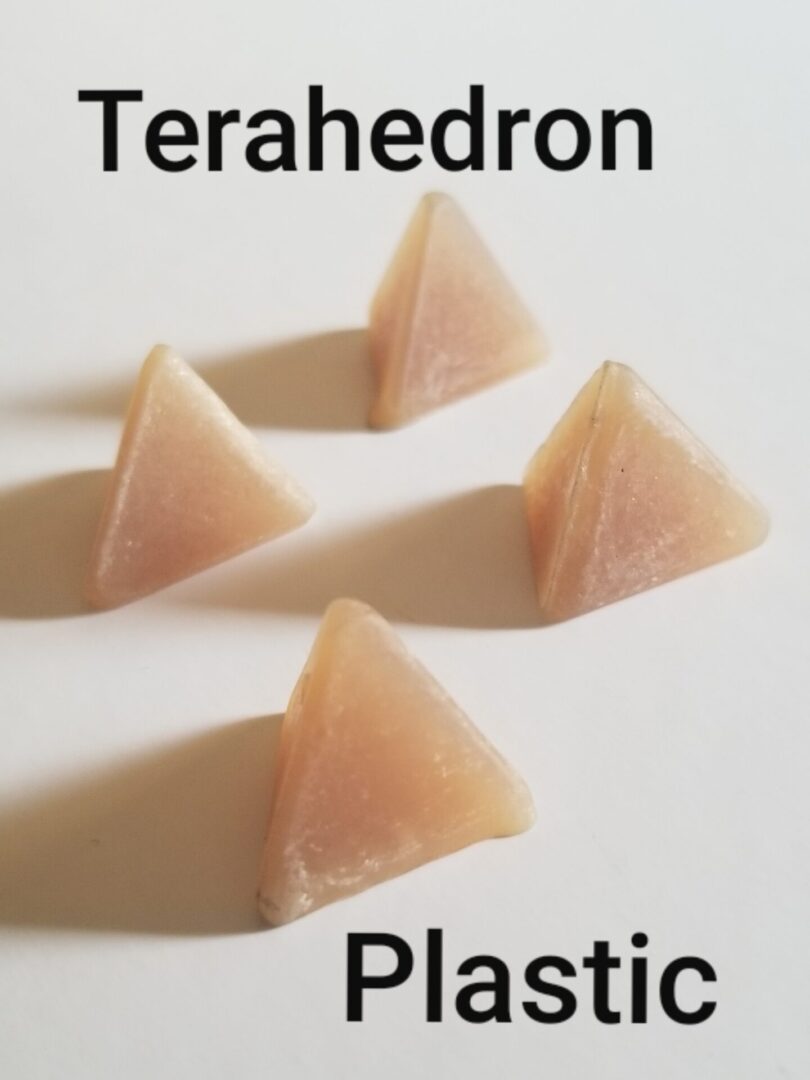

Choosing the Right Media and Compound. The choice of media and compound determines the type of finishing operation. Polishing or refining operations for die-castings are usually performed using plastic media with a mild, alkaline compound. The plastic media can provide a 4 RMS finish on soft metals. The media, being soft and lightweight, can be cut without gouging or scratching. Even though the parts have a low RMS, there is not much glitter and almost no reflected image. Copperplate is heavy enough to fill the fine microscopic scratch pattern of this media. After chrome plating, the parts appear to have been hand-rubbed.

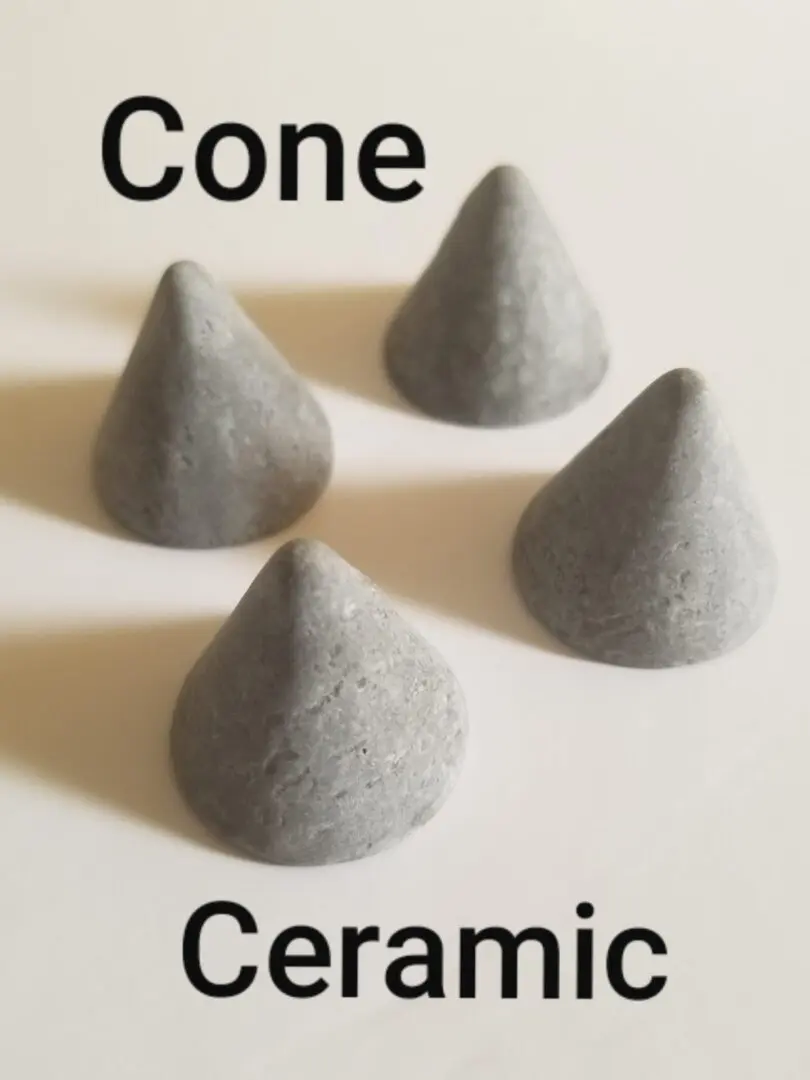

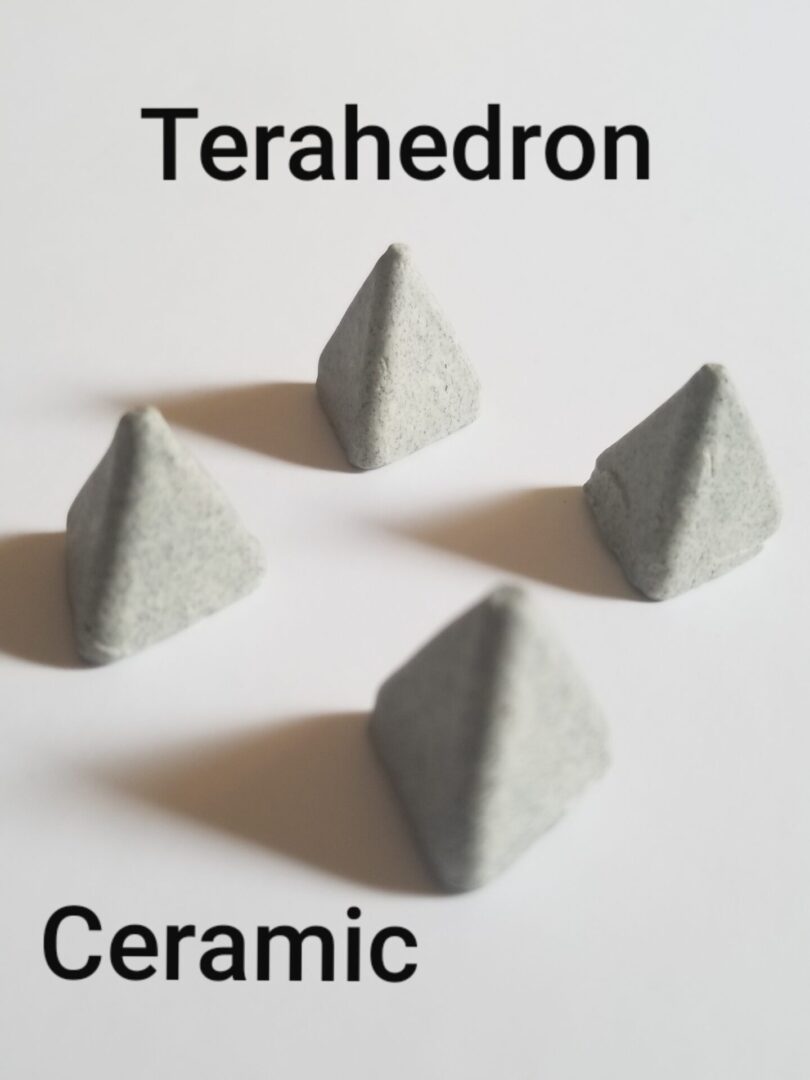

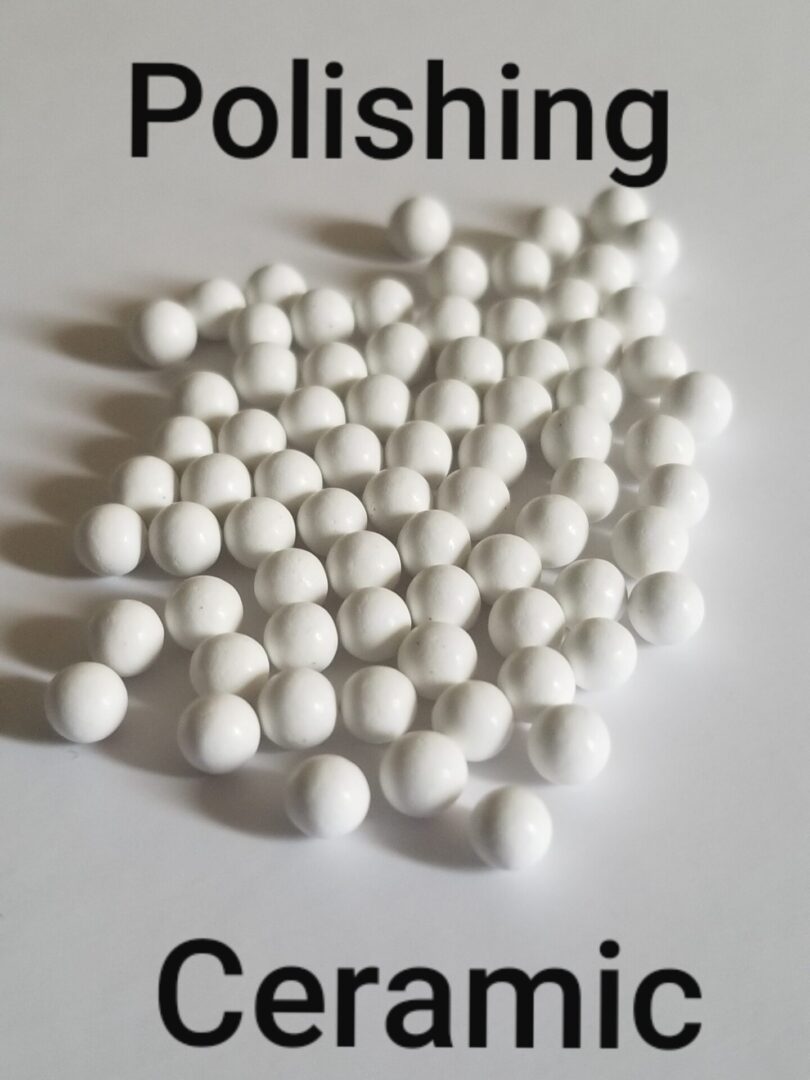

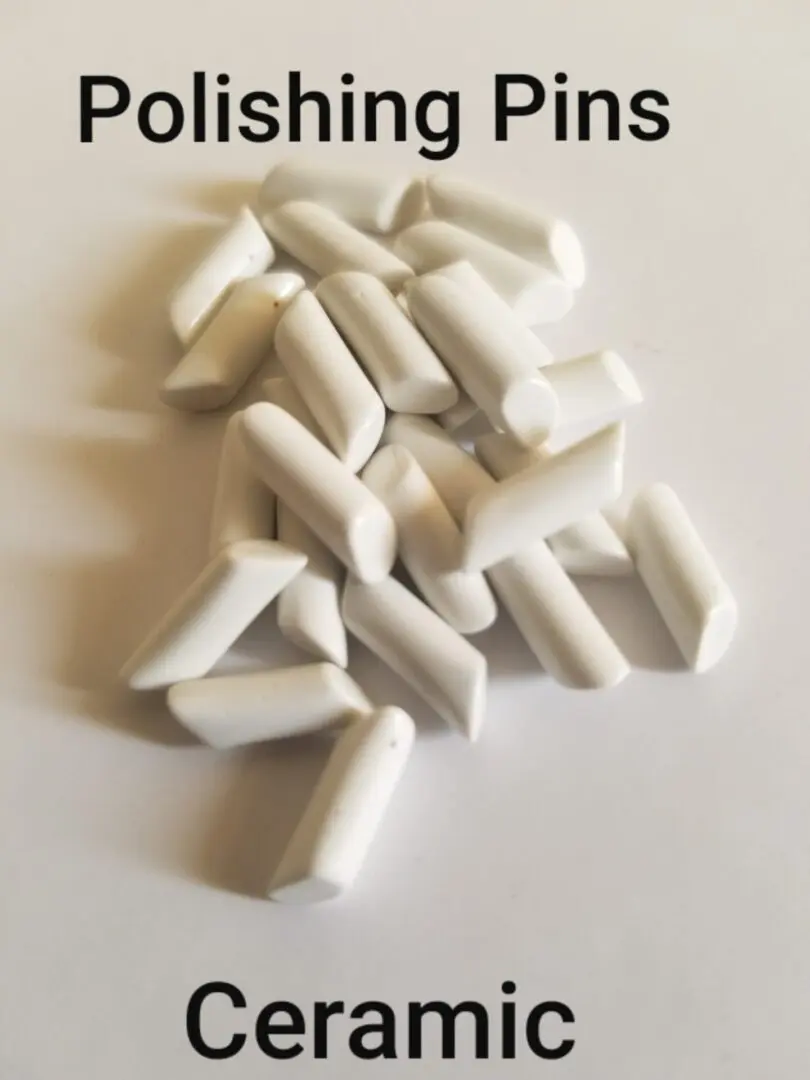

Heavy Cutting With Ceramic Media. Heavy cutting is done using ceramic media. It is more aggressive but does not produce the flatness achieved with plastic media. To obtain a maximum finish on parts with heavy flash or burrs or bad imperfections, rough cutting is first done with ceramic media and then the surface is refined with a short run in plastic media. Die-castings or rubber-molded parts that are to have finishes other than chrome, such as paint or vacuum plating, are treated differently. The thin coatings will not show up well over the dull finish of plastic. Ceramic media is used in a heavily glazed condition. When run with the proper soap, the stones take on a glossy surface, causing the stones to burnish somewhat like steel shot, while maintaining a slight degree of cutting ability. Decorative items with a large degree of detail are run in this manner. Steel parts, such as seat buckles, requiring a good finish prior to plating, are also run this way, but with highly alkaline compounds. Harder metals will be polished to a very high luster and be in the 10 RMS range. Soft metals will have a good shine, but are not as bright as the steel parts.

Finishing Small Die-Cast Parts. Small die-castings can be run piece against the piece, without media, in a dry operation. Parts like electrical fittings or jewelry components are run in this manner. The pieces are run in a vibrator with a small amount of corn cob or sawdust to pick up dirt. You can expect good flash removal without damage to the details or threads. This process is good preparation for vacuum plating. Corn cob or walnut shells can be used for cleaning and polishing.

Providing Edge Radius and Burr Removal. Sometimes, parts to be plated have burrs or need the edges radiused. Usually, ceramic media is used for steel or stainless steel parts, and when practical, plastic media is for soft metals. Ceramic media has a good cutting rate and offers a diversity of shapes and sizes. Plastic media is not an effective cutting agent below the 1/2 inch size. Most of the time, nonabrasive compounds are used, but occasionally an abrasive compound is added to cut fast enough to avoid rolling over burrs.

Degreasing Capabilities. Vibratory finishing is also effective as a degreasing process. The energy developed in a vibratory finisher far exceeds the power range of ultrasonic cleaners. Soils, such as silicone oil or lapping compounds, can be removed, defying an ultrasonic or a vapor degreaser’s capabilities. The pieces can be run with media or, if the part permits, without media. While the parts vibrate, a cleaning compound is circulated through the tub. The vibrating action rubs the parts while churning the cleaner into all crevices. The chips and dirt are flushed out of the tub as the machine is running.

Improving Part to Surface Bonding. To achieve good plating or bonding on plastic, it is necessary to roughen the surface to accept the conductive material or cement. Pieces are sometimes self-vibrated with quartz or pumice added as an abrasive. Ceramic media is added when the part has recesses or pockets. The run is normally only about ten to fifteen minutes long. The parts can be thoroughly rinsed in the vibrator before dumping. This process is an alternative to chemically etching the surface which may be impractical. The vibratory method is an optimal solution since it does not produce fumes and will handle any plastic.

Proper Drying and Rust Protection. Since most of these processes use water to carry away dirt or lubricants, consideration is given to proper drying and rust protection. The most common drying method is a centrifuge with forced hot air. This process is best for small parts. Water displacing dips can be used when the parts are large, but usually leave a film that must be removed before plating. Vapor degreasers can be used instead of a dip, thus avoiding the extra cleaning operation. When the parts have pockets that hold water, it is best to tumble the parts in hot corn cob grit. When the corn cob is kept hot enough, it can absorb the water rapidly without clinging to the parts.

Rust is usually not a problem when the parts go directly into plating, but when they must sit for hours or days, there must be some additional care. The displacing dip usually contains an inhibitor, such as a wax or oil. Otherwise, a chemical rust inhibitor is added to the rinse water or into the water solution in the vibrator. A rust inhibitor and light cutting compound provides rust protection for weeks, even on wet parts, and can be rinsed off in plain water. Parts that run through any of the processes described are generally given one hot rinse to remove the soap or alkali film, with the exception of those dried in a vapor degreaser.